Glass Processing

Heat Processing Equipment for Glass Processing and Production

Several glass processing activities require heat to produce quality glass products for commercial, residential, and industrial applications. To produce glass to the required specifications, glass processing service providers must employ several heating processes that deliver the precise wavelength of energy that suits the particular process. At Casso-Solar Technologies we offer the right solution to meet your heating requirements effectively and efficiently. We have several types of infrared heat processing equipment that are designed to help customers in the glass processing industry. We have the expertise, experience, and technology to design customized infrared systems to suit your requirements.

Types of Infrared Heat Processing Systems Offered by Casso-Solar Technologies

At Casso-Solar Technologies, we strive to provide performance-driven and energy-efficient equipment that provides infrared heat for glass processing. The following are some of the types of infrared heating equipment we offer to execute glass processing activities such as glass screen printing, glass laminating, and much more.

- Spandrel Drying Oven

- Dryers for Digital and Screen Print Inks

- Nip Roller Lamination Line (Pre-Autoclave)

- Non-Autoclave Vacuum Batch Lamination Line

- SentryGlas™ Trim Table

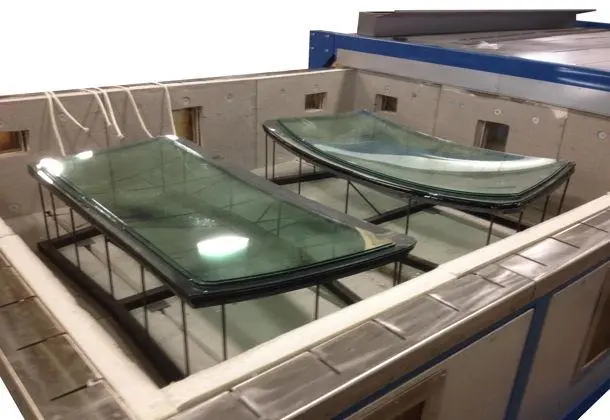

- Glass Bending Systems for Ballistic, Aircraft and Automotive Glass

- Rolling Hearth Furnace for Firing Ceramic Ink

- Glass Casting Furnace

By investing in the right type of equipment, glass processing service providers can have efficient equipment that is designed for their particular process, thus speeding up production.

Beneficial Features of Infrared Systems for Glass Processing

Whether drying various coatings on glass or preheating glass bottles for further processing, we provide the infrared heaters that use specifically chosen energy densities and wavelengths to direct the heat precisely and efficiently to your product. Our infrared heating systems will not only make the right amount and intensity of infrared energy available, but also offer you several benefits including:

- Space-saving and quality-orientated equipment at competitive prices.

- State-of-the-art control systems allowing the equipment to provide consistent and repeatable heat.

- Superior infrared emitters with long-life and minimal maintenance.

- With unique heating filament design, our IR systems helps deliver the right amount of infrared heat for glass processing, thereby helping you form distortion-free, heat strengthened laminated glass for applications in windows, canopies, overhead glazing, domes, and glass lift walls.

Automotive Glass

Casso-Solar Technologies offers a wide variety of equipment for the automotive glass industry that covers numerous steps in the manufacturing process. Utilizing our infrared heaters, we have designed equipment to assist with ink drying and firing, bending, and lamination.

All of Casso-Solar’s equipment is custom designed to fit a customer’s precise requirements; our engineers will work with your needs to tailor-make a system to provide the flexibility needed to produce your current products as well as potential future products. This ensures that the maximum benefit is achieved from a customer’s investment and that the equipment will be useful for many years to come.

Our equipment is designed to achieve maximum uptime with minimal maintenance required to meet the demands of the 24/7/365 production environment that defines much of the automotive industry’s operations. Smaller test equipment is also available for R&D facilities. Call our sales team today to discuss your application.

Architectural Glass

Casso-Solar Technologies has extensive experience designing and providing equipment for the architectural glass industry and has been doing so since the early 1980’s. We offer equipment for all types of processes, including ink and frit dryers, continuous and batch lamination lines, bending furnaces, and firing furnaces.

All of Casso-Solar’s equipment is custom designed to fit a customer’s precise requirements; our engineers will work with your needs to tailor-make a system to provide the flexibility needed to produce your current products as well as potential future products. This ensures that the maximum benefit is achieved from a customer’s investment and that the equipment will be useful for many years to come.

In addition to our standard equipment, we also can design equipment for nearly any custom flat glass application upon request. Our in-house lab performs testing on any new applications to develop the ideal solution. Give us a call to discuss your needs in further detail to see how we can help.

Appliance Glass

Casso-Solar Technologies offers a variety of equipment for the appliance glass industry. In most cases, appliance glass has a coating or screen print applied to it that must then be dried and cured. Our systems have been designed to work with all sorts of common coatings, such as screen-printed inks and conductive glass coatings or conductive coatings used to create bus bars. In addition to drying, we can also supply equipment to fire the conductive glass coating and heat-treat the glass. Once the heating process is completed, glass can be passed through one of our high efficiency cooling systems to bring the product down to a reasonable handling temperature.

Below are links to more detailed information on our primary types of appliance glass systems. Many possible equipment configurations are possible, and our sales team can help you determine what will best suit your needs.

Solar Energy, Photovoltaic, Photo & Electrochromic Glass

Glass fabricators are constantly developing new technologies and applications for their products. A market segment that continues to become larger is the photovoltaic, electrochromic, and solar glass industry. Casso-Solar Technologies can provide equipment for use in laminating these products as well as drying coatings on them. These offerings are similar to our standard architectural glass systems but are modified to meet an application’s specific requirements, such as strict cleanliness standards or accommodating coatings that reflect infrared energy.

In addition, Casso-Solar will work with our partners to supply automated loading, trimming, assembly, and unloading equipment as needed to provide a full-scale solution from end to end for an application. Reach out to our sales team today to learn how Casso-Solar can provide a turnkey solution for your process.

Related Blogs:

Contact our Sales Team to discuss our extensive offerings and find out how we can deliver equipment custom-designed for your needs

Get a Custom Infrared Solution for Your Application

With six decades of infrared technology expertise, Casso-Solar is ready to address your project needs. Reach out to our specialists today.