Infrared Furnaces

Equipment for processes requiring temperatures above 1000F (538C). Casso-Solar specializes in furnaces for the glass manufacturing & processing industry.

Infrared Furnaces for Manufacturing and Heat Processing Applications

Our industrial furnaces are extremely well insulated to ensure that our customers can achieve the high temperatures they require for their processing needs, without excessive heat loss to the surrounding environment.

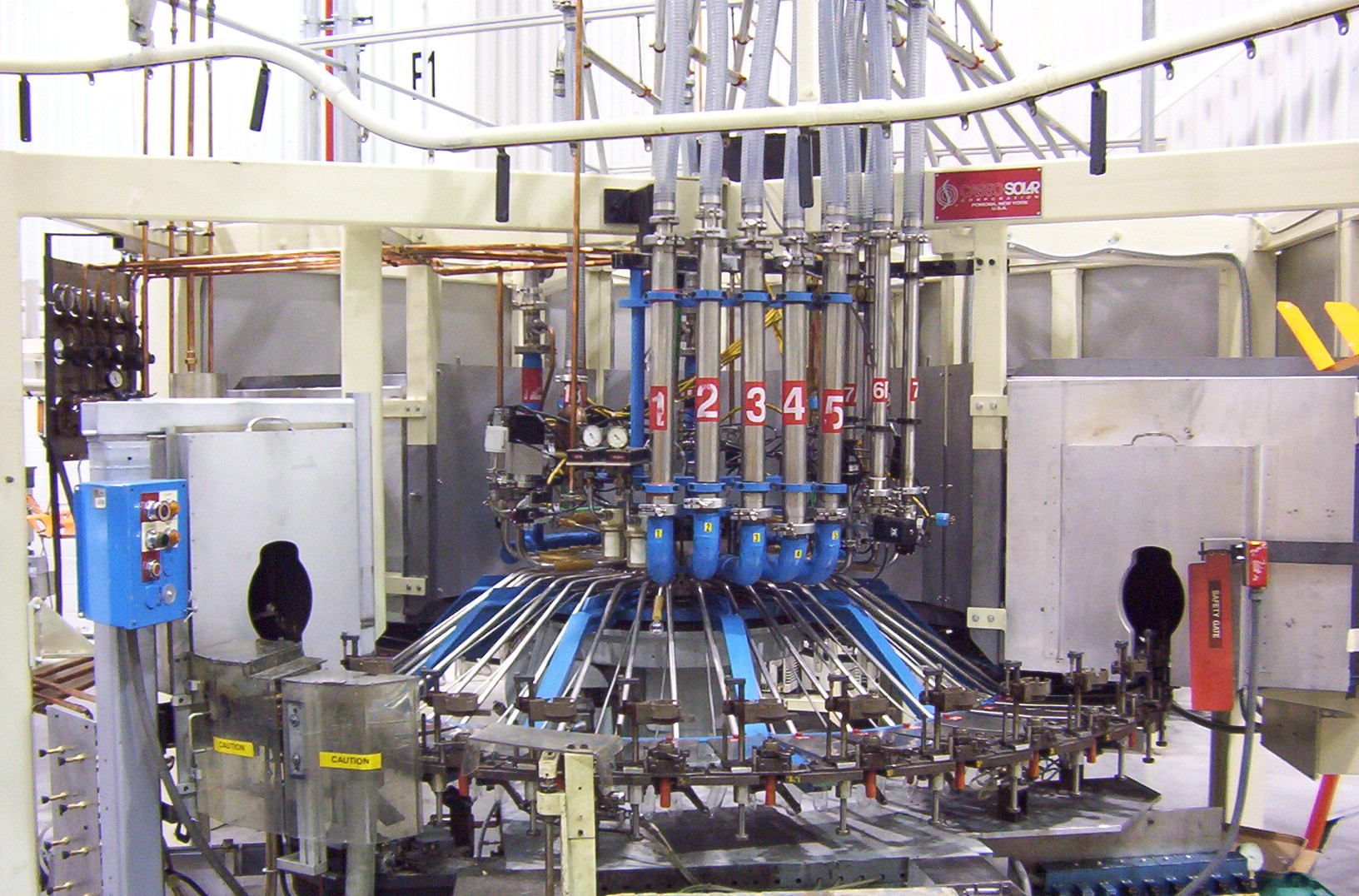

Ballistic Glass Bending Furnace

Furnace specifically designed for bending glass for ballistic applications, up to 100mm total thickness. Can be built to process multiple parts simultaneously.

Casting Furnace

Casso-Solar Technologies glass slumping and casting systems move the system floor within close proximity to the multi-zoned heater bank.

Automotive Glass Bending Furnaces

Casso-Solar Technologies Multi-zone Graphical User Computer Control for complex shapes with localized programmable 3-Axis Crease Heaters that follow the glass as it bends in the tight radius areas.

Aerospace Glass Bending Furnace

Aircraft/Aerospace Glass Bending Furnace typically used for production of thick parts (up to 75mm) with precise curvature requirements. Full surface molds are commonly used in these furnaces.

Ink Firing and Rolling Hearth Furnaces

Equipment for Firing and Curing Inks. Dryers combined with rolling hearth furnaces can fire decorative or conductive coatings into the glass. The glass is then annealed or partially heat strengthened, for further processing.

Architectural Glass Bending Furnace

Bending furnaces for large sized architectural glass. Flexible zone configurations to allow for a wide assortment of products to be made.

Custom Infrared Furnace

Custom Designed Furnaces to Fit Applications in Any Industry

Related Blog Posts

Electrochromic Glass Production with a Rolling Hearth Furnace

Things You Need to Know About Infrared Industrial Furnaces

All Important Question Answered About Infrared Ovens

Get a Custom Infrared Solution for Your Application

With six decades of infrared technology expertise, Casso-Solar is ready to address your project needs. Reach out to our specialists today.